When you’re shopping for school lockers for your facility, you want to be sure you’re choosing a durable material that can withstand the impact of students unloading their books, gym clothes, sports gear and other belongings. There are many different factors to consider when shopping for lockers for your school. Read on to find out the five questions you should be asking.

1. How durable is the material?

School lockers face a lot of harsh wear and tear daily, so it’s important to choose lockers that are made of a durable material that can withstand this use.

The traditional option for hallway lockers is metal but they can come with a lot of drawbacks. They’re prone to dents with minimal impact which can compromise the aesthetics of the lockers and will end up costing a lot of money for repairs and replacement.

A impact test was conducted following ASTM standards that showed Duralife Lockers had 59 times greater resistance to impacts when compared to metal lockers.

2. How much maintenance do they require?

Constantly having to perform maintenance on your school lockers will become expensive in the long wrong. You want to be sure that the lockers you’re choosing are low maintenance to save you from this cost.

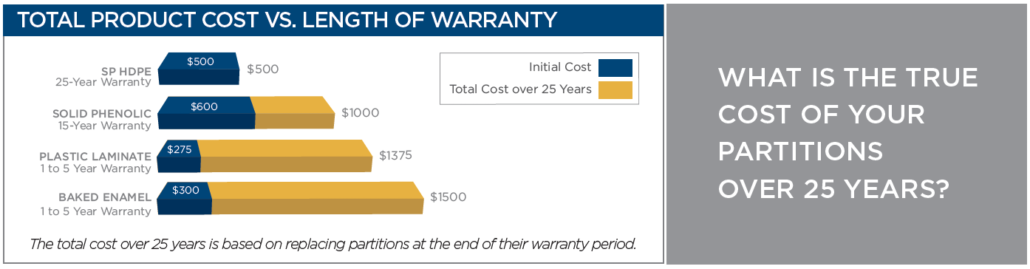

Traditional metal lockers have a lower initial cost than plastic lockers, making them an economical choice for schools. However, there are hidden costs such as additional expenses associated with cleaning, painting and the general maintenance of these lockers on an annual or semi-annual basis which may be overlooked.

By comparing the true cost of a traditional metal hallway locker to a Duralife HDPE locker over a 20 year period a study was done to take into account the initial cost, maintenance, dent and scratch repair, painting cost, graffiti removal and replacing damaged and corroded parts to create a cost of ownership model. Within 2 years, Duralife HDPE lockers are less expensive than metal. In 20 years, the accumulated savings are substantial.

3. How much noise do they produce?

The noisy clanging that comes from shutting a metal locker can be distracting as it rings throughout the hallways, so look for an option where the sound is muffled.

Duralife Lockers are 3 times quieter than metal lockers and reduce noise in the hallway. This eliminates distractions from the hallways and leads to a better learning environment. The difference between that is a metal locker noise would be equivalent to an alarm clock 2 feet away where the Duralife locker noise is considered similar to that created by a washing machine.

4. Are the lockers made of sustainable material?

Some major traditional metal locker brands do not meet the strictest standards for air quality and sustainability. These products are not Greenguard Certified. The Greenguard Certification Program gives assurance that products designed for use in indoor spaces meet strict chemical emissions limits. This contributes to the creation of healthy interiors.

Duralife Lockers are Greenguard Gold Certified and meet the strict criteria for products intended for use in schools, as well as other environments where children spend a lot of time. With Duralife Lockers, you can be confident that the lockers are not having a negative effect on your school’s air quality.

5. Are the lockers visually appealing?

It’s also important that the lockers are aesthetically appealing in your facility. You want people to come into your school and see it as a respectable environment. DuraLife Lockers have appealing vents throughout and a clean-looking surface. There are also built in handles and combination locks that are recessed to improve student safety.

To learn more about Scranton Products’ DuraLife Lockers download our free eBook, The Ultimate Guide to HDPE Plastic Lockers for Schools.