Parents in 2017 have several options available to them when it comes to the education of their children. Public schools, traditional and online; privately owned and funded academies; homeschooling; and finally charter and magnet schools, are the options of today. All of these schools are vying for parents’ attention and for available funding. Each have their pros and cons, and although public schools are still the most widely chosen of the options, charter and magnet schools are bright and eager up and comers in the education marketplace. Competition for the mix of public and private funds is stiff, and the pressure is on to perform.

The Pressure Is On For Charter & Magnet Schools To Get High Marks From Parents

Charter and magnet schools, though operated similarly to public schools, are relative newcomers as viable educational venues. They offer specialized curriculum and are often tasked to out-perform traditional public schools in several key areas, including concept and design. Drawing from a mix of public, secure funding as well as private funds, many charter schools now have more options. One of the areas that charter schools can shine is in school design.

You Only Get One Chance To Make That First Impression

As the old adage goes, you only get one chance to make a first impression. Many parents and visitors are touring your school more than ever, and the impression your school makes can impact your school’s opportunity to gain new students. One of the first areas they view is the hallway, and a bright, modern, clean and open area are all positive elements that help make that first impression a good one.

With their superior aesthetics, Duralife Lockers® are sure to make an impact in your hallways. The sleek, clean, modern design and bright color options such as yellow, red and royal blue instantly make a positive statement about your school, while design details such as flush venting and recessed handles, reinforce the clean, updated look.

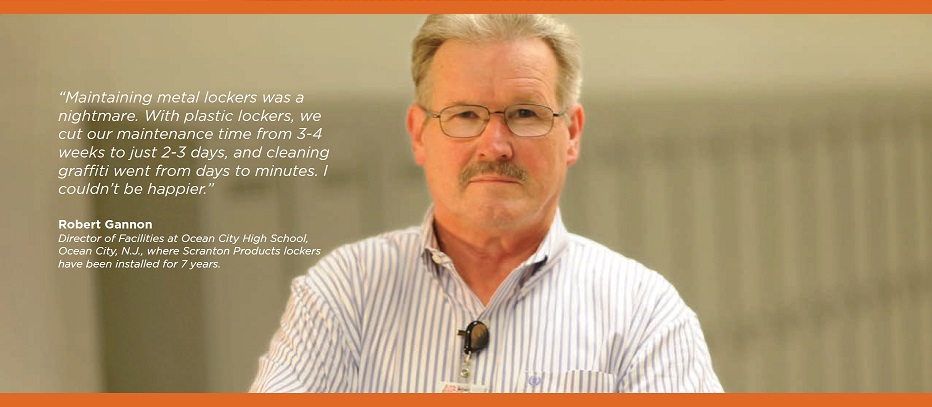

Unlike metal lockers, Duralife Lockers® stay attractive throughout their lifetime. Made with solid-core HDPE, Duralife Lockers® are highly resistant to impacts, dents and scratches; graffiti wipes off easily; and the non-porous surface resists bacteria, mold and mildew. Another big plus is that HDPE lockers never need painting, making them the low maintenance, smart “green” choice. As you can see, Duralife Lockers® impress on many levels, and are fast becoming the choice for the busy hallways of today’s well-designed schools.

View our case study that highlights the reasons why this charter school made the smart decision to install Duralife Lockers® in their school. If you need more information, please contact one of our sales specialists to learn more. https://www.scrantonproducts.com/contact/