It’s the most wonderful time of the year during winter break. The students get a nice vacation from their studies during the holidays. As for the school facility manager, you get to play catch up, thanks to the empty halls and classrooms. Even though the students use this time to relax, sleep in, and get together with friends and family, you need to use this time wisely to make sure everything is in order for the remainder of the winter months.

Here’s 10 things school facility managers should take care of during winter break to make sure their school is in tip-top shape.

Maintain Your HVAC System

Heat is crucial during the frigid winter months, so you’ll need to perform a few audits to make sure everything is functioning at its best. Look for any components that may need a replacement, so you can take care of it during the break. Any type of issue that can prevent your school from being heated may actually prolong winter break, so be sure to keep the system in great shape.

functioning at its best. Look for any components that may need a replacement, so you can take care of it during the break. Any type of issue that can prevent your school from being heated may actually prolong winter break, so be sure to keep the system in great shape.

Winterize Your School to Retain Heat

While properly maintaining your HVAC system is a crucial step on the winter break checklist, you’ll also want to be sure you’re not wasting any heat. Find any weak areas that result in your school losing heat and energy. You’ll want to air seal these areas, so your school doesn’t suffer from drafty rooms or areas that can’t retain heat.

Inspect Your Pipes

Winter brings the cold, and if your school isn’t properly heated, this can cause more problems than just frigid temperatures. If your school suffers from the cold, or loses power, this can have a huge effect on your pipes. These pipes can freeze and burst, so you’ll want to be sure that not only are they in great shape, but they’re getting enough heat to remain at any optimal temperature.

Perform a Test of Your Generator

Due to the snow and ice buildup on tree branches, they can often buckle and break under the tremendous weight and the brisk temperatures, which can be troublesome if there are any nearby powerlines. If you lose power, which is a significant certainty during the winter, you’ll be relying on your backup generator to make sure your school remains at an acceptable temperature, so your pipes don’t freeze and any electronics don’t suffer.

Replace Faulty or Broken Components

On day one of winter break, you’ll want to perform an inspection of your school and its various fixtures and

The doors and fixed panels used in the Eclipse partition system provide both high design and privacy. Here we show how to ensure proper gapping and consistency on all panels and doors in order to achieve the desired sleek lines.

The doors and fixed panels used in the Eclipse partition system provide both high design and privacy. Here we show how to ensure proper gapping and consistency on all panels and doors in order to achieve the desired sleek lines.

components. This can include lights, water fountains, electrical outlets, or even radiators. Check each of these components to make sure they’re working, or if they need to be replaced before the students and teachers come back to resume the school year.

Inspect the Roof

During the winter, the roof of your school takes quite a beating from the snow, rain, and ice, especially if your roof is flat and doesn’t have any slopes or angles that can help combat the elements. You can work to remove any of the snow and ice build-up with a shovel or rock salt, but you’ll also want to look for any issues or problems that could affect the integrity of your roof. Be sure your drain pipes are free of debris and caulk any noticeable cracks.

Clear the Snow & Ice

Depending on how hard the weather hits your area, this may be a continuous process during winter break. You’ll want to clear the parking lots and designate the snow piles to areas out of the way. Clear the walkways and paths to your school’s entrances, and salt the ground to help reduce any ice buildup.

Invest in New Floor Mats

The floors in your school can take quite a beating during the winter, with students tracking in clumps of snow and even rock salt from the walkways. You’ll want to get some heavy-duty floor mats for the entryways to help reduce the snowy debris from damaging your floors. For the best results, place heavy-duty floor mats outside the entrances to pick up most of the snow and salt, which will reduce the amount actually making it into the school.

Start a Germ & Bacteria Removal Plan

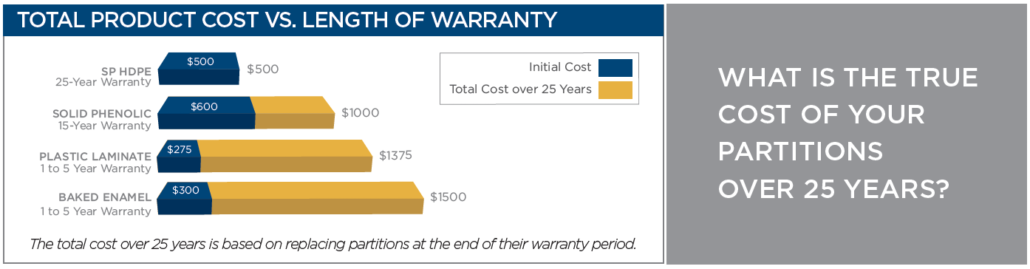

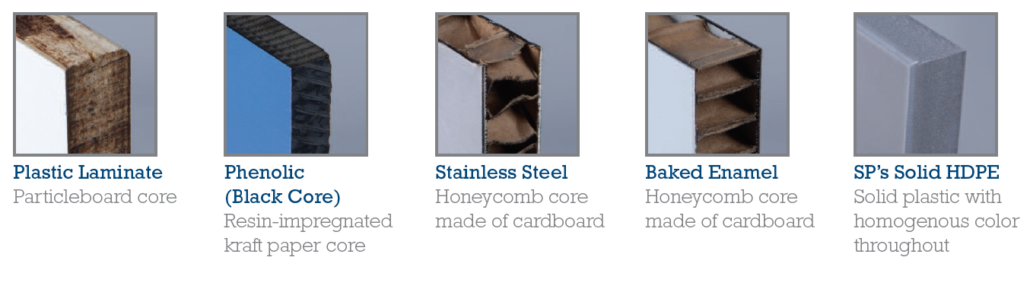

School absences and sickness are rampant during the winter, so one of the best ways to combat this is by focusing on areas with considerable germ and bacteria buildup. The most susceptible areas are the restrooms and the locker rooms. A thorough cleaning can do the trick; however, if there is mold within the components, like your partitions, you may need to find a suitable replacement. HDPE plastic partitions can drastically reduce sickness because they don’t absorb moisture and won’t sprout mold.

Get Your Painting Done

Due to the lack of students filling the hallways and classrooms, now’s the time to get some painting done. If there are components or features in your school that are starting to fade in color, or if they’re chipping, you can get the painting done without having to worry about the VOC emissions affecting student health. Be sure to do this early in the break, so the paint can be dry, ensuring your school is free of the paint smells by the time students and teachers return. You can even invest in HDPE lockers to help avoid any locker painting in the future.

Use your winter break wisely and get these crucial services completed, so you can avoid any major problems that occur throughout the winter.

Want some more tips and tricks on most effective facility maintenance methods? Download this free eBook, The Ultimate Guide for Facility Maintenance & Property Solutions, from your friends at Scranton Products.