HDPE Material

Solid plastic color throughout

Phenolic Material

Resin impregnated kraft paper

SCRC Material

Fibers, dyes & resins with color throughout

MYTH: Phenolic, SCRC and HDPE toilet partitions are manufactured from the same material

FACT: High Density Polyethylene (HDPE) bathroom partitions are comprised of high density polyethylene resin & pigments. Phenolic bathroom partitions are comprised of a melamine sheet then multiple layers of resin impregnated kraft paper. Solid color reinforced composite (SCRC) bathroom partitions are made from a homogeneous composite of cellulose fibers, dyes & resins with a GraffitiOff™ surface coating. Independent testing reveals Scranton Products™ HDPE is a better material choice to withstand the harsh environments of commercial bathroom partitions.

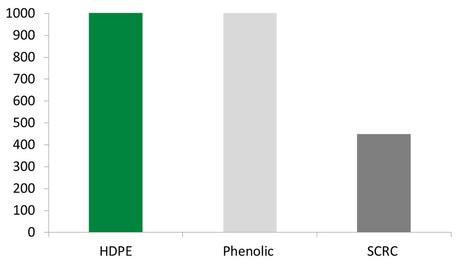

Comparing the numerous laboratory test throughout this document HDPE, Phenolic and SCRC were graded on a scale of 1—3, 1 being the least favorable and 3 the most. Testing shows that Scranton Products HDPE is the best material choice with a score of 15 out of 18 and then Phenolic with 13 out of 18 and SCRC with 10 out of 18.

MYTH: Phenolic, SCRC and HDPE partitions are all resistant to mold and mildew.

FACT: HDPE exhibited no microbial growth during the testing period. In just 21 days Phenolic had mold and mildew growth and an additional amount of growth within 28 days. Bathroom partitions are placed in environments where materials are susceptible to mold & mildew, therefore it is important to choose a material that is microbial resistant.

Testing conducted in accordance with ASTM D3293. The results are shown in above. Samples were scored on a 0-10 scales, where 10 is the best microbial resistance. Test performed in 2013.

MYTH: SCRC and phenolic bathroom partitions have a more durable surface than HDPE bathroom partitions.

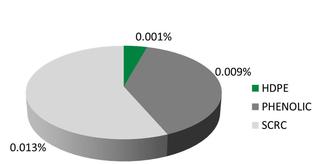

FACT: HDPE has the best abrasion resistance with the lowest surface wear. Phenolic and SCRC have a higher surface wear indicating a lower abrasion resistance than HDPE. The test performed mimics the surface abrasion that would result from normal handling, cleaning or polishing. Once the surface of Phenolic or SCRC have been scratched or worn, stains may be more difficult to remove and some may leave a ghosting effect.1

1 Referenced from Bobrick Advisory Bulletin TB-60 Toilet Partition Cleaning & Maintenance

HDPE has the highest abrasion resistance

The abrasion resistance of various bathroom partition materials was measured in accordance with ASTM G195 using the CS-10 abrasion wheel. This wheel was selected for this test because of its mild to medium abrading action, like that of normal handling, cleaning or polishing. Testing performed in 2013

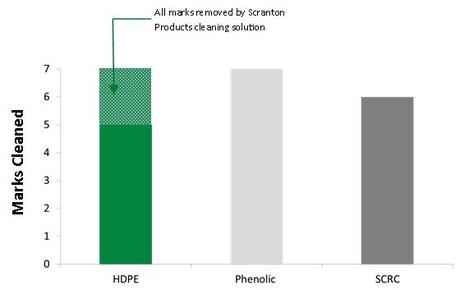

Graffiti Resistance

MYTH: Phenolic and SCRC toilet partitions have better graffiti resistance under all circumstances than HDPE bathroom partitions.

FACT: Using Scranton Products® recommended environmentally friendly cleaning solutions graffiti was removed in all instances from HDPE. It should be noted that both Phenolic and SCRC have an exterior coating to prevent graffiti that may deteriorate over time and may require specialized maintenance such as waxing. HDPE, on the other and does not have an additional coating and no specialized maintenance procedures are necessary.

Testing was conducted in accordance with ASTM D6578 . The test provides a standard set of conditions that can be used to evaluate the graffiti resistance of a surface. Seven marking agents and six cleaning products were used in the evaluation. Testing performed in 2013

Screw Retention

MYTH: HDPE, SCRC and Phenolic partitions have the same screw retention capabilities.

FACT: Test results show that HDPE performed with very high screw retention. In a laboratory test using the same fastener type for comparison, SCRC testing failed at less than half the pull force to remove the same fastener. A portion of the SCRC surface broke free during the test (see photo to the right), exposing the inner layers of the material.

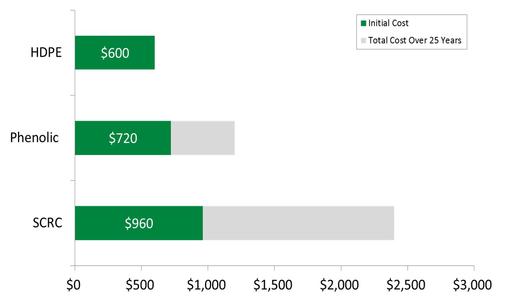

Total Product Costs vs. Length of Warranty

MYTH: Phenolic and SCRC bathroom partitions are only slightly more expensive than HDPE bathroom partitions.

FACT: Scranton Products® HDPE plastic has the lowest initial cost and provides the lowest cost of ownership due to its performance, durability and long warranty. HDPE solid plastic toilet partitions cost significantly less than the other two materials over a 25 year period.

The total cost over 25 years is based on replacing partitions at the end of their warranty period.

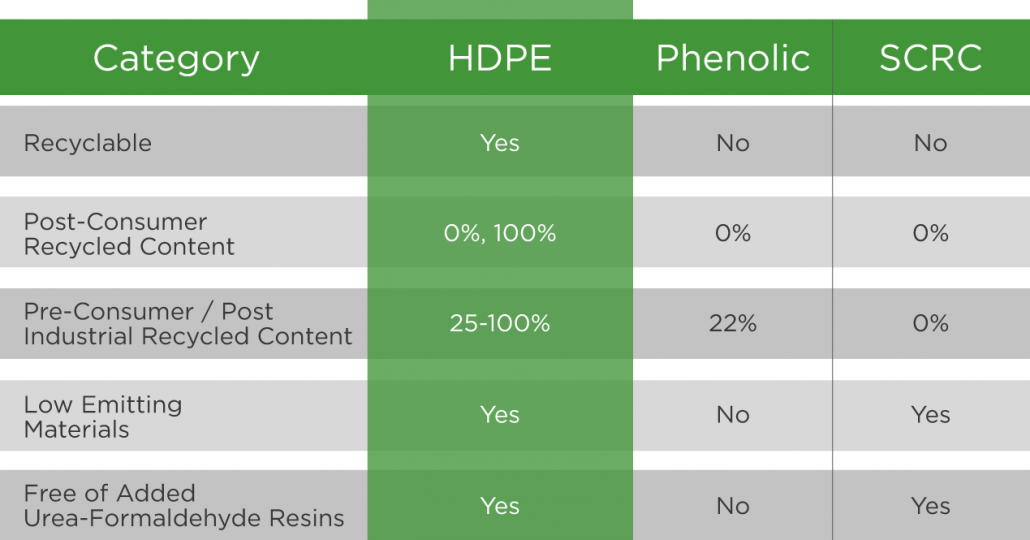

Sustainability

MYTH: Phenolic and SCRC bathroom partitions are as sustainable as HDPE bathroom partitions.

FACT: HDPE is 100% recyclable and is available with up to 100% post-consumer content. Scranton Products® HDPE material has 25-100% pre-consumer content. Phenolic and SCRC are not available as 100% post-consumer and are not recyclable. SCRC does not contain any pre-consumer content. HDPE does not contain any added Urea-Formaldehyde resins.